Isopropyl nitrate and DII levels in racing diesel fuel

What controls the optimum level of any ignition improver in any typical racing diesel fuel? To answer that question one has to understand just what diesel ignition improvers (DII) do or what their major purpose in diesel fuel mixtures are. We are told that DII’s effectively increase the cetane value of the final fuel mixture. The cetane value is simply the ease of compression ignition of the fuel mixture when compared to pure cetane. Kerosene has a cetane number of +75, truck diesel min cetane number is 40, pure chemical cetane 100.

Definition – Cetane value

The cetane number measures the ignition quality of a diesel fuel. It is the % volume of cetane ( n-hexadecane, Cetane Number = 100 ) in alpha methyl naphthalene ( Cetane Number = 0 ), that provides the specified standard of 13 degrees ( crankshaft angle ) ignition delay at the identical compression ratio to that of the fuel sample. Currently, heptamethyl nonane - with a Cetane Number of 15 - is used in place of alpha methyl naphthalene because it is a more stable reference compound. It is measured in special ASTM variable compression ratio test engine that is closely controlled with regard to temperatures ( coolant 100C, intake air 65.6C ), injection pressure ( 1500psi ), injection timing 13 degrees BTDC, and speed (900rpm ).

The compression ratio is adjusted until combustion occurs at TDC ( the ignition delay is 13 degrees ). The test is then repeated with reference fuels with five cetane numbers difference, until two of them have compression ratios that bracket the sample. The cetane number is then determined by interpolation, and the higher the Cetane Number, the shorter the delay between injection and ignition. Now, if the fuel is pure hydrocarbons ( does not contain cetane number improving agents like alkyl or amyl nitrates ) then the cetane number can be predicted fairly well using some physical properties, such as boiling point and aniline point.

If we therefore look at individual components in our diesel fuel, Kerosene, diethyl-ether and castor oil we find the following values for cetane number in the table on the left. The component that varies the most will have the larger effect on cetane value in the fuel mixture, therefore adjusting the oil and kerosene level will significantly effect the ignition performance of the final fuel mixture.

Rightly or wrongly we normally leave the diethyl ether level constant, and change the Kero and oil proportions. As Kerosene is the major component, changing, this concentration will effect the ignition timing (cetane value).

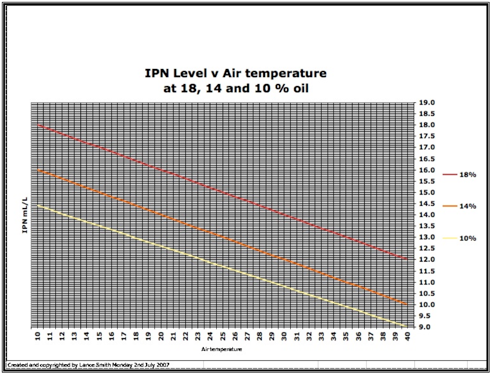

The graph below takes account of the oil level and the air temperature in working out the optimum DII level. Use this graph as a guide only, individual engines will behave differently so one must optimise the DII level to suit each individual situation.

The actual graph above can be downloaded from the “Useful Data” page as a .pdf file.